Plastic material goods have been in demand in a variety of industries for decades, as a result of their overall flexibility and ease. However, the production process of developing plastic-type material products made a great progress way since the earlier time. One of the more impressive and groundbreaking Plastics Rotomolding operations which have captured the attention of plastic material companies throughout the world is Rotomolding. This technique is slowly becoming a favored production method in a variety of industries as more businesses are switching from conventional methods to this particular new technique. In this particular blog post, we shall discuss how Rotomolding has turned into a innovative procedure for plastic material producing.

Weblog Entire body:

1. What is Rotomolding?

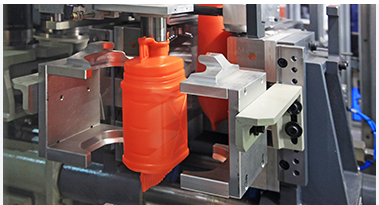

Rotomolding, which is also generally known as Rotational Molding, is a developing procedure that is used mainly to make hollow plastic material items of all styles, dimensions, and colors. It is a inexpensive strategy for creating big plastic material products, and contains been used and accepted around the world. This original procedure generates a variety of items required for numerous industries like agriculture, vehicle, healthcare, aerospace, sports, and recreation.

2. How exactly does Rotomolding operate?

Rotomolding requires the melting of plastic-type resins within a mildew which is then rotated in order that the molten plastic-type resin may be distributed all over the mold’s inner work surface. The evenly spread out plastic resin later solidifies right into a last product design mainly because it cools. The procedure of Rotomolding is easy yet sophisticated simply because lots of factors come into thing to consider, like resin kind, mold temperature, pattern time, and chilling amount, among others. However, Rotomolding delivers lots of positive aspects over other producing processes, particularly if you think about the quality of the ultimate item.

3. Benefits associated with Rotomolding

One of the most important great things about using Rotomolding as a producing method is its adaptability – it provides the flexibleness to produce items of virtually any condition, size or color. In comparison with other developing operations, Rotomolding merchandise have a softer surface complete since there are no weld facial lines or air vents, contrary to other styles of molding procedures. Also, because Rotomolding goods are hollow, they are typically extremely lightweight. Above all, the capability to develop uniform wall structure thicknesses for any product makes it possible to produce products, which include physical objects with exceptionally intricate geometries that would be hard or extremely hard to produce through other operations.

4. Ecological Advantage

Aside from the benefits explained above, Rotomolding offers some significant enviromentally friendly benefits over other production procedures. This process generates very small squander, making it possible to reuse creation scrap quickly. The process’s production devices are also energy-efficient, meaning it comes with a decrease carbon dioxide footprint compared to other developing operations.

5. To put it briefly:

Certainly, Rotomolding is undoubtedly an incredibly progressive and cost-powerful process that has revolutionized the way in which industries make plastic-type material merchandise. The ability to make exclusive forms, dimensions, and colors which can be perfectly and uniformly dispersed has created this method the most preferred choice in many sectors. If you’re trying to find a great-good quality yet cost-effective strategy to make big plastic-type merchandise with minimal waste creation and are seeking environment-pleasant developing, Rotomolding is the go-to method.